Delvo DLV30A/45A/70A Automation series

Features

Designed for automatic assembly robot

| 30A series | 45A series | 70A series(High Torque) | ||||||

|---|---|---|---|---|---|---|---|---|

| Low Speed | Standard | High Speed | Low Speed | Standard | Low Speed | |||

| Model | Standard coupling | DLV30A06A-N(AA) J | DLV30A12A-N(AA) J | DLV30A20A-N(AA) J | DLV45A06A-N(AA) K | DLV45A12A-N(AA) K | DLV70A06A-N(AA) K | |

| Coupling with flange | DLV30A06A-F(AA) J | DLV30A12A-F(AA) J | DLV30A20A-F(AA) J | DLV45A06A-F(AA) K | DLV45A12A-F(AA) K | DLV70A06A-F(AA) K | ||

| Coupling with M41 screw | DLV30A06A-M(AA) J | DLV30A12A-M(AA) J | DLV30A20A-M(AA) J | DLV45A06A-M(AA) K | DLV45A12A-M(AA) K | DLV70A06A-M(AA) K | ||

| Torque (Nm) | Low torque spring (Accessory) 0.4 – 1.6 | 2.0 – 4.5 | 3.8 – 7.0 | |||||

| High torque spring (Installed) 1.2 – 3.0 | ||||||||

| Free Speed (rpm) | 650 | 1,200 | 2,000 | 650 | 1,200 | 650 | ||

| Screw Size (Nm) | Machine Screw | 2.6 – 5.0 | 4.5 – 6.0 | 5.0 – 8.0 | ||||

| Tapping Screw | 2.5 – 4.0 | 4.0 – 5.0 | 4.5 – 6.0 | |||||

| Mass | Standard coupling | 700 | 780 | |||||

| Coupling with flange | 760 | 840 | ||||||

| Coupling with M41 screw | 740 | 820 | ||||||

| Power Consumption (W) | 45 | |||||||

| Input Voltage | 100 V AC, 50/60 Hz | |||||||

| Starting Method | External input signal | |||||||

| Input signal | Start signal / Forward signal / Reverse signal (5 – 24 V DC) | |||||||

| Output signal | Torque-up signal (Voltage under 30 V DC and current 20 mA) | |||||||

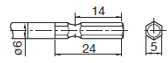

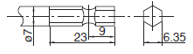

| Bit Type (mm) |  |

|

||||||

| Standard Accessories | Bit NK31 × 2 × 6 × 70: 1 pc. Low torque spring: 1 pc. | Bit NK35 × 2 × 7 × 75: 1 pc. | ||||||